DIY VESA display mounts

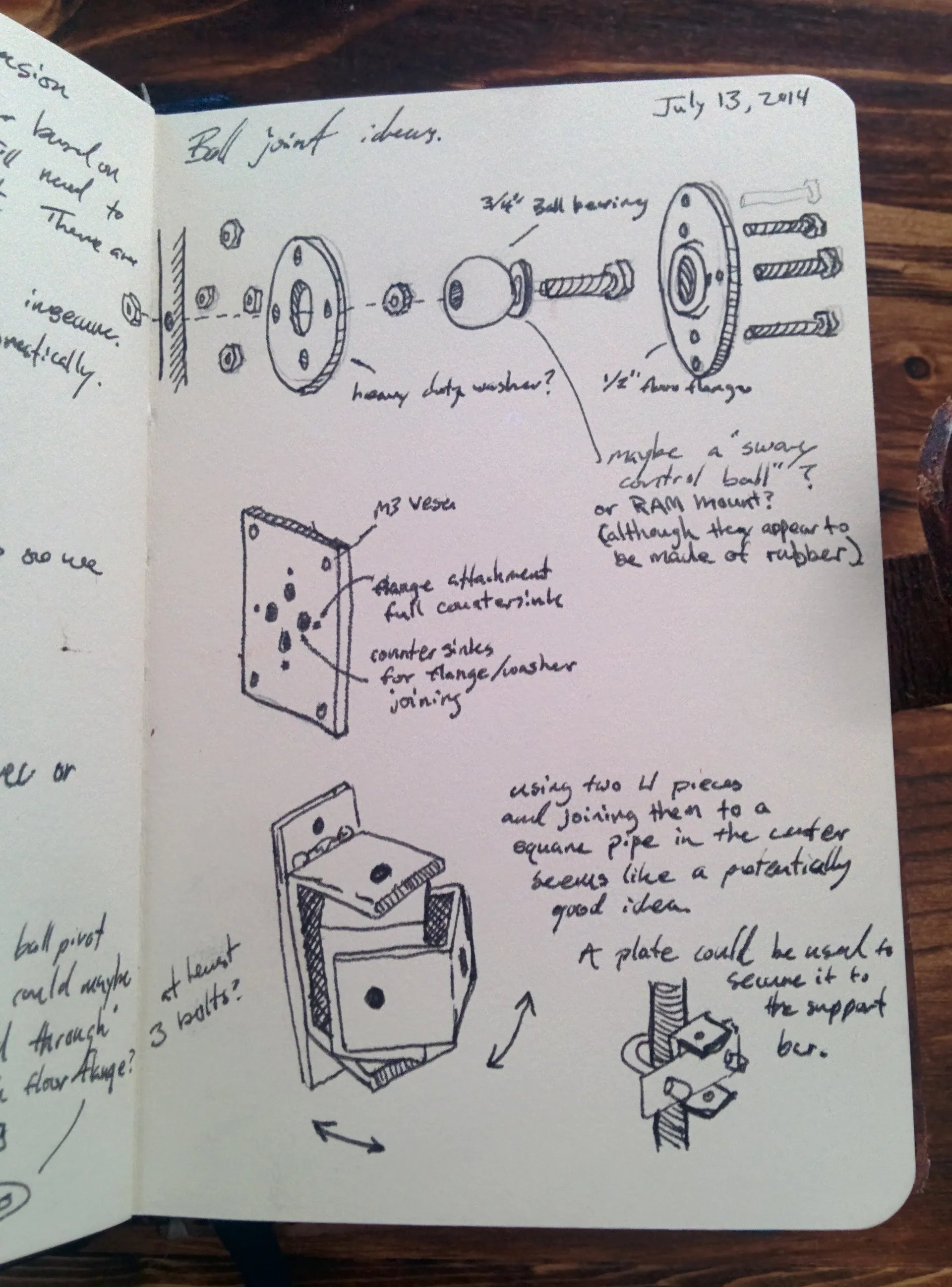

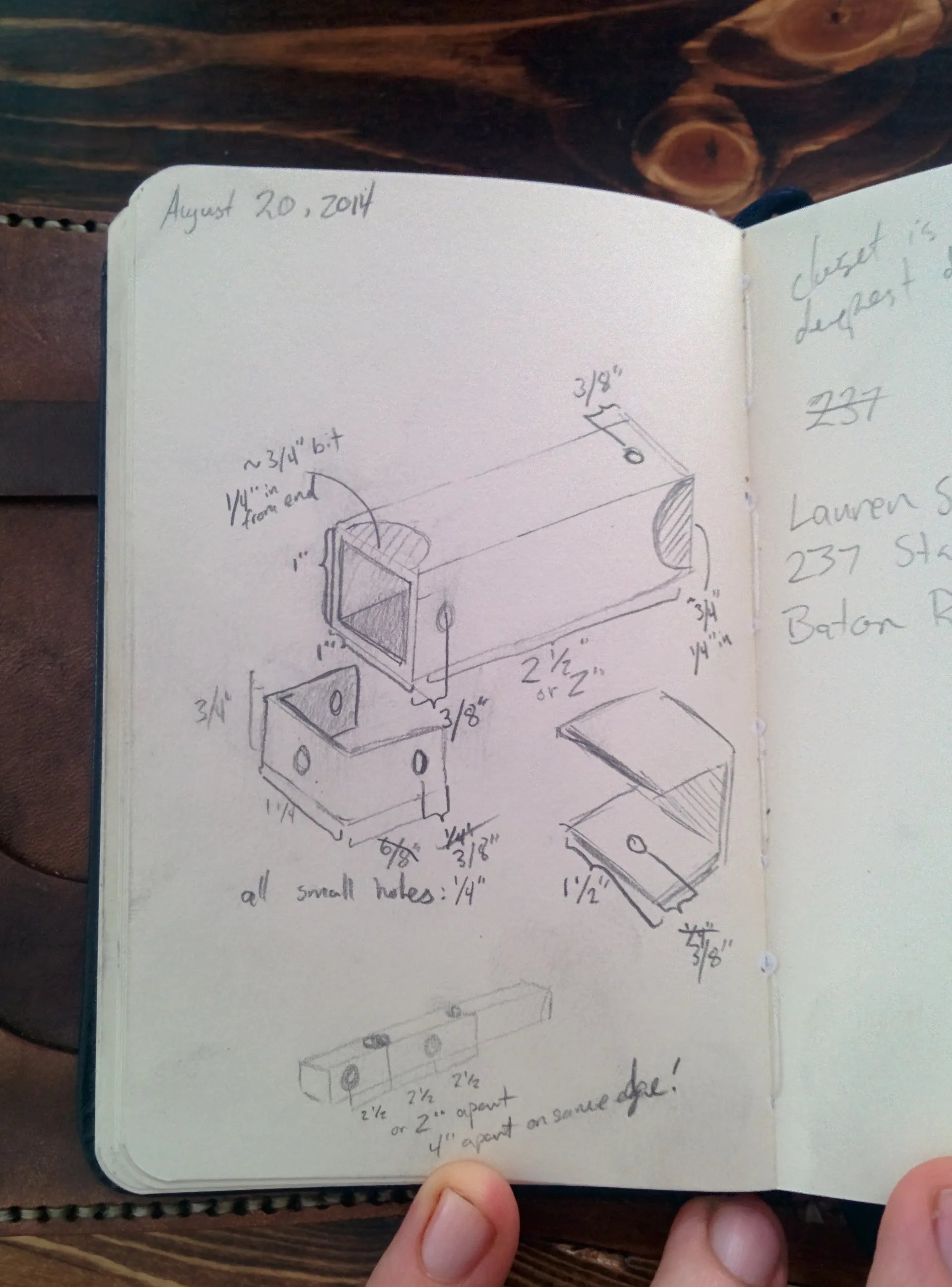

In need of a solution for how to mount my computer displays. I set out to sketching a few general concepts. My goal was to keep material costs low while still having mounts that I would feel safe placing the lives of my displays in without spending the amount needed for fancy commercial grade VESA mounts.

This was not my first attempt at building a monitor stand. A few years prior, I assembled a stand thing from segments of aluminum U-channel, hinges, and suspension cables (for stability). While that solution worked for 3 small monitors, its stability was quite precarious; if one of the suspension cables came loose, the whole thing would come down. I knew I wanted something more robust than that.

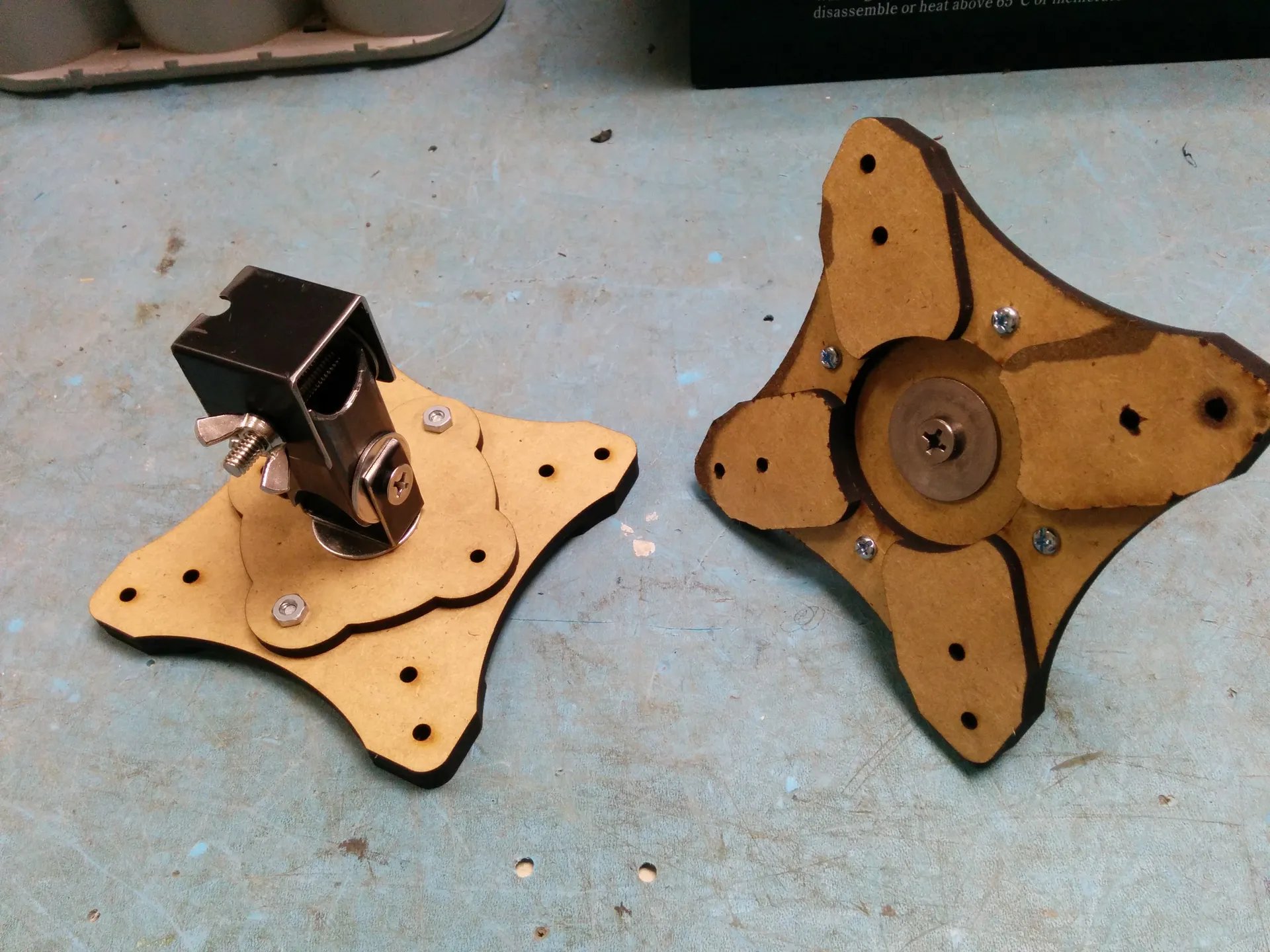

After some cutting, drilling, and smoothing down with a wire brush, I had the beginning of a hinge assembly.

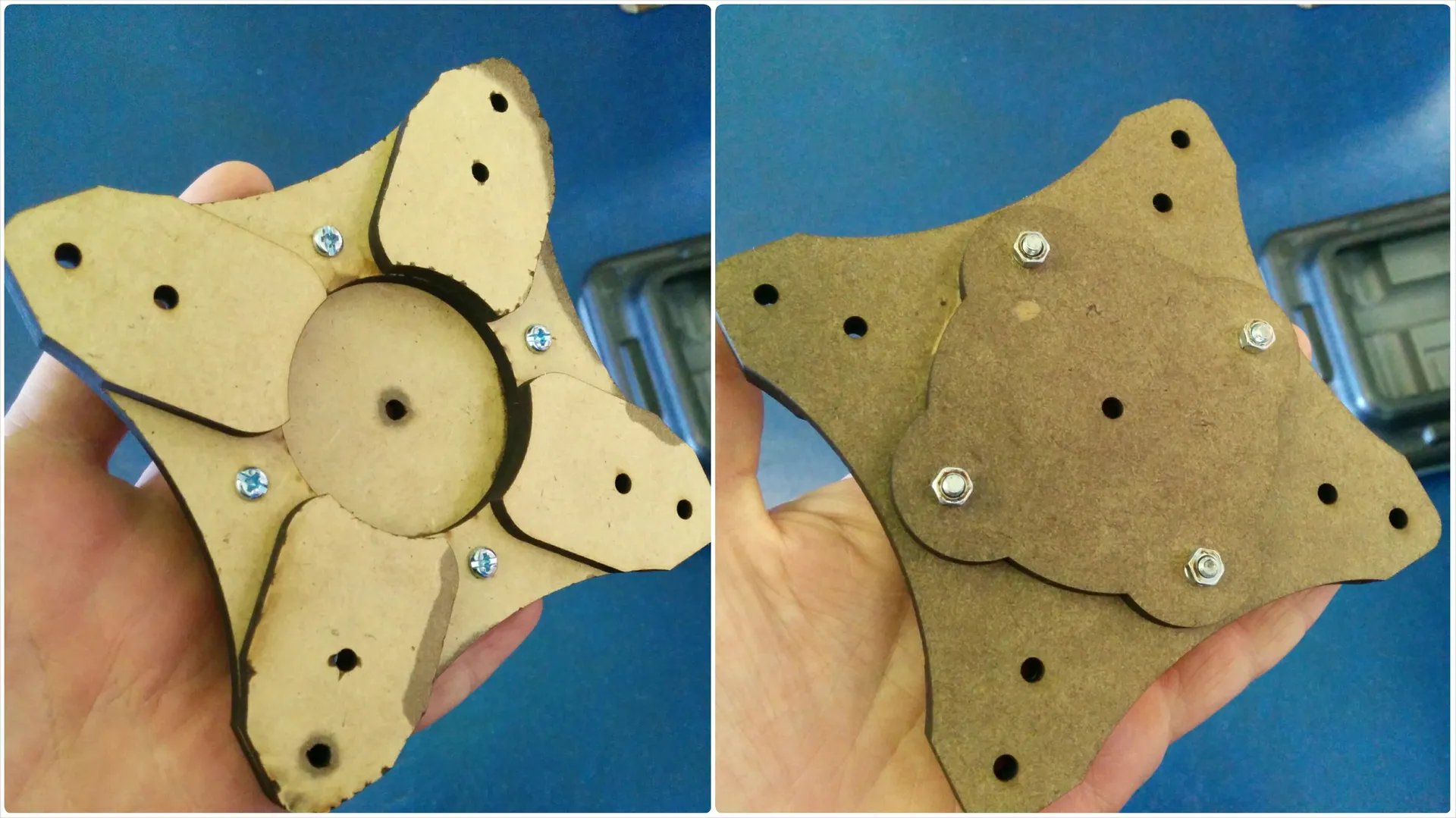

For the mounts themselves, I figured I should be able to assemble them out of sandwiched MDF. I used Inkscape to produce the laser cutter template to cut the MDF (including drill holes!). This made production easy; all I had to do was cut the parts out of MDF with the laser cutter, glue them together with wood glue, and reinforce the layers with some small bolts.

Although I did fail to anticipate how to mount the mount to the bracket component. I ended up drilling a larger hole in the center portion to accommodate a larger bolt (3/4"). The entire weight of the monitor kinda hinges on that bolt, so, no skimping!

The final step was figuring out how to mount these to the hanging iron pipes. After some experimentation, I landed on the idea of using a U-bolt with a piece of pine behind it to fill the gap. I rounded the inside of the pinewood pad so it was concave, while the opposite side is convex to match the curve of the U-bolt. Not only did the wood spacer provide added stability by preventing the U-bolt from rotating, it also provided enough friction against the support pipe to obviate the need to tighten them down. Due to the gentle torque of the stand, it’s enough to hold the monitor on to the pipe. This means that moving the monitor up and down is as simple as lifting the monitor to remove the rotational torque, and placing it where you want. I figured I could put end-caps on the pipes if I wanted a safety fallback, but so far I’ve not had any monitors slide off.

Update 2021-07-28

These mounts are still going strong, supporting my 4K monitor!